Welcome to Sirah Lasertechnik

Sirah Lasertechnik is a private company that was founded in 1998 and quickly grew into the leading manufacturer of tunable lasers. The product range covers nano-seconds pulsed dye lasers, narrow-linewidth ring dye lasers, ring Titanium-Sapphire lasers, and high-repetition-rate dye lasers.

The company is based in Grevenbroich Germany, where the lasers are developed, engineered and manufactured.

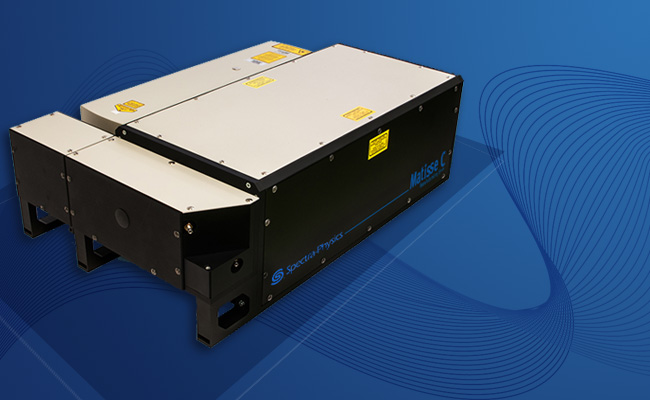

Our Scientific Lasers

Tunable CW Single-Mode Lasers

- single-frequency continuous wave laser radiation

- large tuning range: 206-4200 nm

- ultra-narrow linewidth < 30 kHz

- more than 7 W average power

- dye and Ti:Sapphire laser design

- modular design

High-Energy Pulsed Lasers

- nanosecond pulsed multimode laser radiation

- large tuning range: 190-16000 nm

- narrow linewidth down to 1 pm

- high energy laser pulses up to 0.5 J

- repetition rates up to 100 Hz

- dye and Nd:YAG laser designs

- modular design

High-Repetition-Rate Pulsed Lasers

- nanosecond and picosecond pulsed multimode laser radiation

- large tuning range: 190-1050 nm

- narrow linewidth down to 1 pm

- high average powers up to 60 W

- high repetition rates up to 150 kHz (nanosecond pulses) / 80 MHz (picosecond pulses)

- dye and Ti:Sapphire laser designs

- modular design